Mr. Rusty strikes back! This reel knob

was apparently acting wobbly weird and the line roller wasn't even spinning. The victim in this case is a pimped up Daiwa Certate and it's time for a strip search!

|

| Mr. Rusty left something unpleasant on this reel. We'll soon find out what and where. |

First

thing that was taken apart was the pimped up handle and knob. No rocket

science, just a cap and a screw in the way of revealing the unpleasant

gift from Mr. Rusty.

|

| Knob

slides off and behold! Mr. Rusty left an explosive dump here. Rust

looked to have eaten up quite a bit out of the inner bearings most exposed to salt

water, which is still stuck on the shaft as pictured. Bearing shield came off and that's a really bad case of rust and

corrosion. The outer bearing seems perfectly fine. |

The

knob bearing closest to the handle seem to have exploded and grinded

some of its own bits into the the potpourri of shield, balls, races to

dust and rust.

|

| It

took quite a bit of time and rust remover to work deep into the

corroded parts in order to dislodge the fused inner bearing race (blue

arrow) on the shaft. Thoroughly chewed up shields (green) and busted

balls (pink) only fell apart after rust remover seeped through the

entire pile of rust over a period of time. |

Mr.

Rusty left some nasty scars of corroded pits on the shaft but isn't

critical. All it needs now is a new bearing and proper coating of marine

grease packed into the entire assembly.

|

| New bearings being loaded with marine grease before fitment back into the handle shaft. Existing outer bearing cleaned and greased too. |

Next

up, line laying roller refused to spin. Screw removal was a little

difficult too, I suspect it's overly enthusiastic thread locker used

here as the screw is usually made of marine grade stainless steel that

can withstand salt water corrosion without breaking any sweat.

The shaft's aluminum, pretty much corrosion resistant.

|

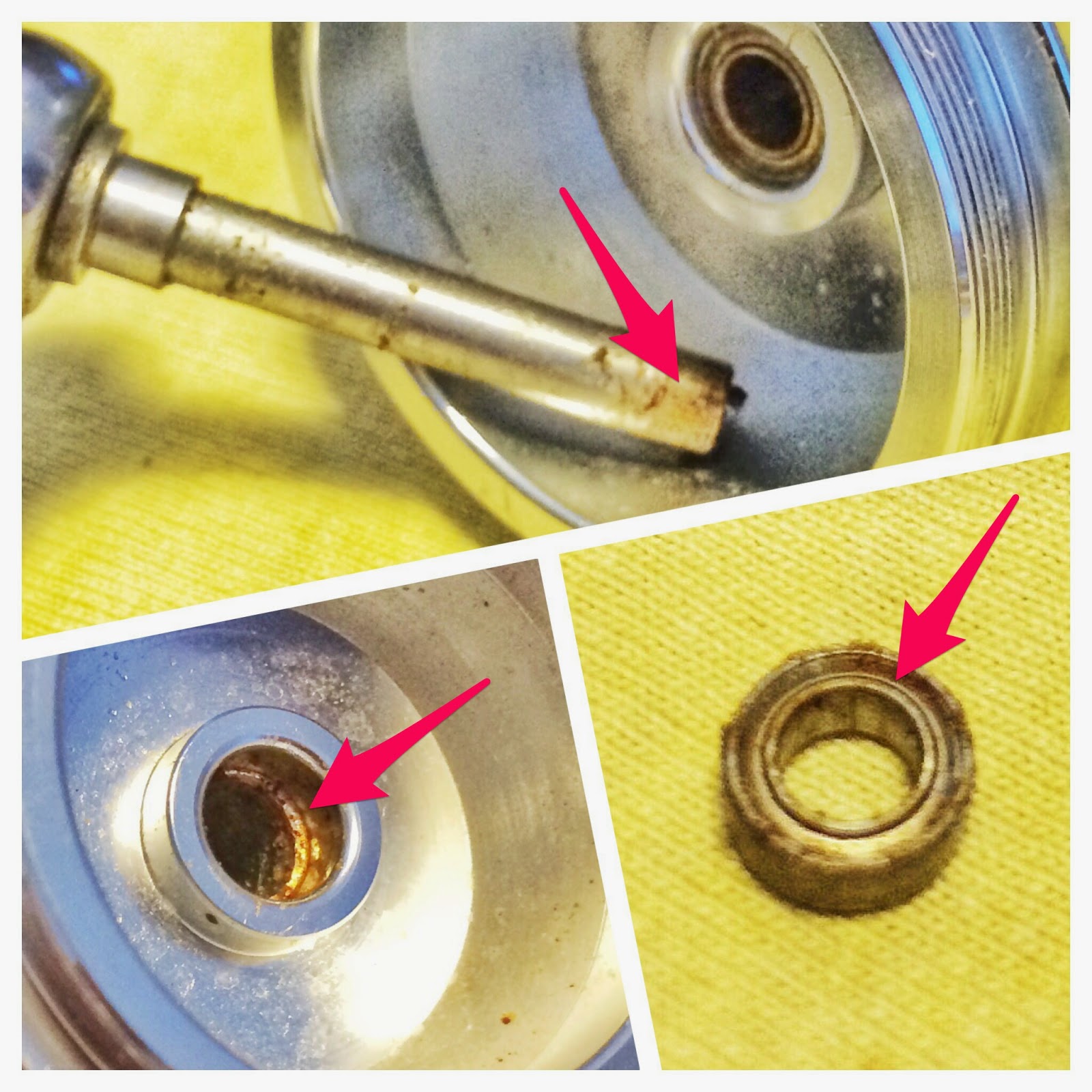

| Thread

locker (red arrow) was found everywhere in the line roller shaft,

including the inside of the bearing (white and red powdered stuff).

Really bad stuff to be found in bearings. There seem to have a bit of

rust but mostly jammed up thread locker's preventing the bearings to

spin freely. It's causing quite a bit of challenge to remove the entire

assembly as it's as good as fused together with so much thread locker

everywhere. Luckily, after cleaning, the bearing seem to work fine only

with slight roughness. |

Cleaning of the line

roller assembly was a little tricky as you need to physically remove the

solidified material between tight creases like screw threads and worse

of all, inside the bearings. This calls for steel bristle brushing and

also good amounts of contact cleaner to remove any oily residue so that

new marine grease could be packed into the entire assembly.

The

remainder of the reel service was child's play after the above fiasco.

Just a quick cleaning and new application of marine grease is all it

needs. The only thing to be careful would be to avoid messing up the

magseal.

|

| Floating

shaft & spool seat sleeve looked well used, still plenty of grease,

no damages found. Cleaned, greased and good to go. |

Avoid

the magseal and you'll be left with just the gear box to deal with. You

don't even need to mess with the one-way bearing. That's if it's

spinning smooth and stopping without play.

|

| Gearbox

looks good, dry and like new. Just a quick clean up, wear and tear check, and add a fresh coat of marine grease. Nothing out of the ordinary and it's good

to go. |

The crack shaft bearing on the handle side seems a bit rough and a simple 2 step clean up with new grease packed in would do just fine. A 2 step clean up usually involves degreasing & contact cleaning after in order to replace lubrication in the bearing. Tougher grime or gunk would need the 3rd step involving an ultrasonic cleaning bath for a thorough cleaning.

|

| No rust, but some light dust or gunk might have snugged in. Out goes the dirty grease and in goes new marine grease. |

What have we learned today?

1.

Go easy on the thread locker. What I usually do is use a small 'precision

screw driver' to dip into the thread locker bottle/nozzle and then dab

it over a few spots on screws. I don't even coat the entire screw. If

too much was accidentally applied, just clean it off with paper

towel before it dries. It doesn't even need to be reapplied upon next removal

or the next, it stays there long enough to hold the screw from coming

off. I only see a need for reapplication when there is absolutely no

friction when removing the screw.

|

| Steel brushed existing screw to strip off old thread locker gunk (white arrow). Light dabs of new thread locker and rub it around just a little towards the tip (red arrow). |

2. Mr. Rusty can cause explosive

damages to bearings if left unattended for too long. Early detection is

key to stopping Mr. Rusty leaving unwanted gifts for your reel. Or

you'll have an excuse to pimp it up with exotic parts.