After a recent off shore trip to Pekan hauling some decently sized diamond trevallys, a friend noticed that his Shimano Biomaster was starting to make noise under load. A quick visual and external inspection revealed that the line laying guide wasn't spinning. No surprises there as this is first part to usually fail when offshore fishing often with lots of salt water exposure.

|

| This Biomaster isn't the salt water variant and to my knowledge recent Shimano's don't come in salt water variant below 4000 sized reels. |

|

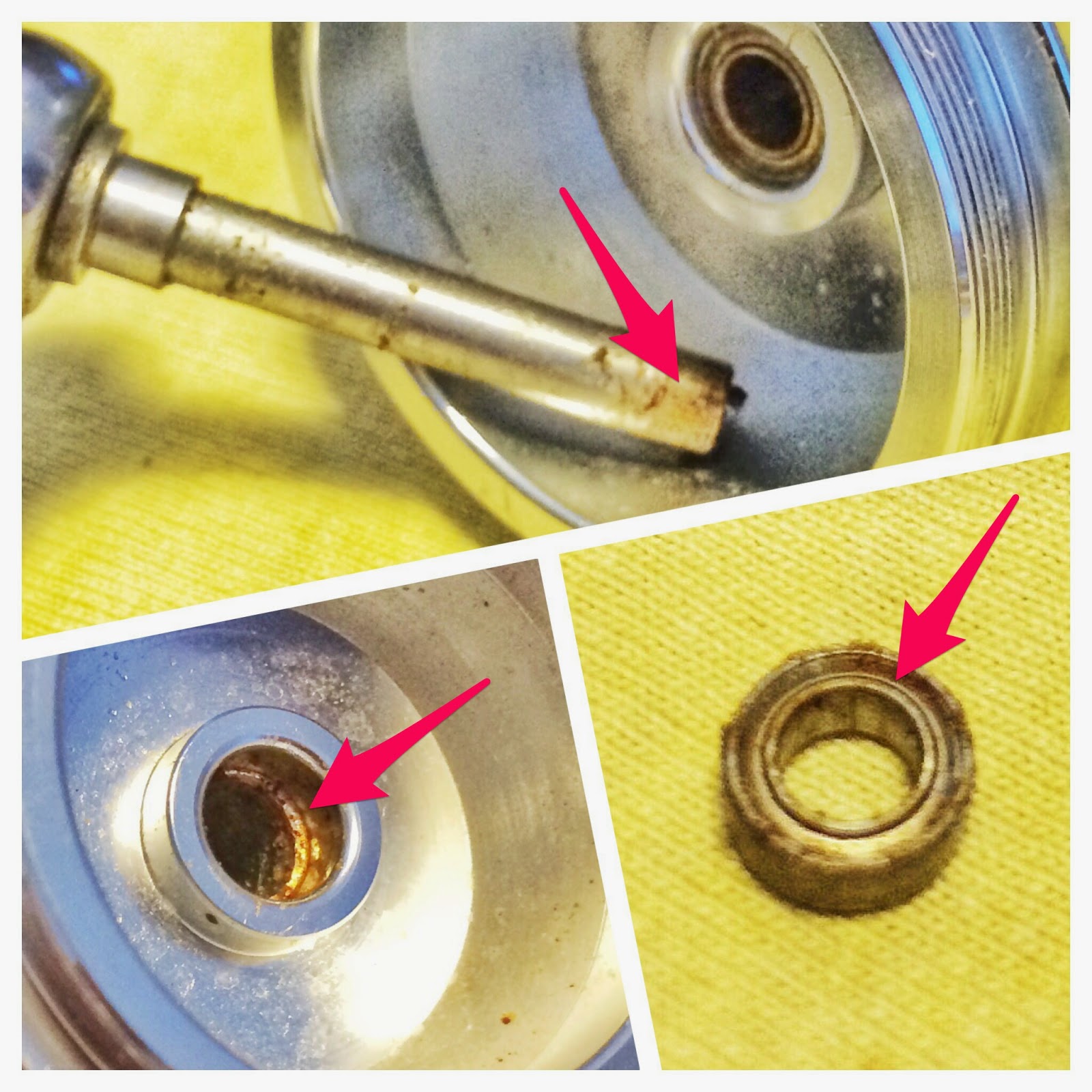

| After market knob with an open outer cap allows water to easily splash into the bearings. When removed, the culprit was easy to spot with gunk and rust everywhere on the shaft as well as the bearing housing. Luckily, they are mostly light surface damages. Bearings stuck as I suspect rust has caught up inside. |

The line roller set doesn't look so good upon disassembly. There was some force binding damages on the bail end cap and the bearing wasn't spinning as a result of rusty balls.

With a jammed up bearing, the only way to rebuild this is to clean it ultrasonically and see if it's ok for a rebuild. The rebuild was ok after the ultrasonic bath but not 100%. This means that the bearing is good to go fishing but grinding sound may not be entirely eliminated. A quick check with the owner says that he doesn't mind trying it out first to see if he can live with it.

I prefer to replace any space/air in the line laying assembly so that water doesn't have any space to fill. This will serve as a very good seal against water intrusion at the same time lubricating the bearings for long periods of time. On top of that, line roller bearing's function is to take heavy torque load as priority, not speed, the likes of spool support bearings for bait-casters.

Upon opening up the gearbox for a regular check-up and service, the sight was a bit shocking with corroded pits seen all over the main gear. Some of the gearing tooth were also affected with slight pitting.

|

| Box was clean but needs a nice protective layer. Corroded pits can be seen everywhere (red arrows). |

Some of the pits were on the gear tooth and some of the tooth were also showing signs of good use and worn off bits.

|

| Some deep pits, cannot be removed (red). Well worn gears most likely from heavy cranking while fighting fish (blue). |

There isn't much to be done with pitting but to give it a nice steel brush down to remove damaged bits off the surface and give it a new coat of protective marine grease.

|

| Pits are still visible but a good layer of marine grease should keep it going for a long time to come. Nicely greased up box too. |

This reel has put up some serious fight against quite a bit of fish as you can see from the collected gunk of fiber and grease on the drag stack.

|

| Move along, nothing to see here with standard drags and nicely used gunk. Don't need messing about if it ain't faulty. |

No comments:

Post a Comment