I've received quite a bit of questions about bearings and comparisons between different types and application. There are no better ways to explain this than to do a simple test to reveal sufficient information for you to make an informed decision. A humble reminder, I'm not an engineer, just a desktop research hero with itchy hands wanting to take things apart to see how things work. If you feel that my findings are questionable, please do drop a line and I'll try to address it as best as I can or even derive a slightly better test.

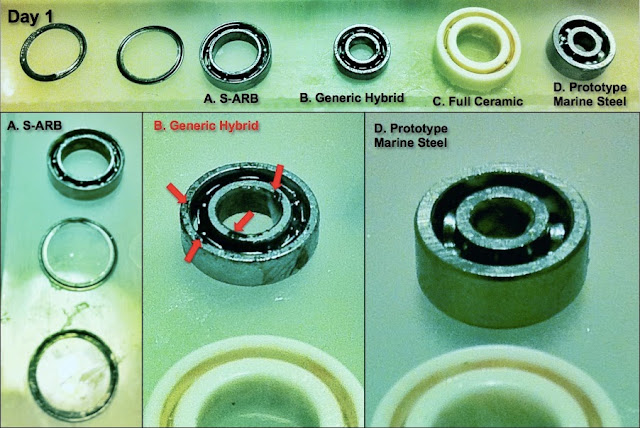

On day one after several sprays of salt water and leaving out to dry, signs of rust start to appear on the generic hybrid bearing B's stainless steel races but the salt water grease was holding up nicely protecting the areas properly covered. Shimano's S-ARB, full ceramics and prototype bearing stood up very well with no signs of rust at all. Impressive.

Day 2. The boring bits first, A, C & D gave nothing as usual. B show even more rust and starts to spread it's share of rust around the salt water. The grease was starting to fade and rust starts to seep in creating more corrosion damage on the entire stainless steel races, assuming the ceramic balls inside doesn't react to any of the rust.

After day 2, bearing E arrived, a high grade hybrid ceramic bearing was prepped and treated with half rubbed salt water grease and salt water sprays. I left the 1st 4 bearings alone with no torture test done to it (assuming without much accelerated corrosion) while I treat bearing E with 2 days of corrosion test to bring E up to speed with the first 4 bearings. Again, A, C & D gave nothing. B didn't like the salty treatment at all. E was reacting very well with only a slight hint of rust seems to appear around the salt water but not on the bearing surface. Curious, don't ask me why or how as I don't have the answer to this.

A clean up after to check surface damages. Again, A,C & D gave nothing away. B was badly damaged with deep corrosion seen around the entire bearing stainless steel races, the bearing was able to rotate but with friction and damage grinding feel to it. It's a dead bearing by now. Bearing E was holding very well with no signs of corrosion damages to the curious 'rust patch' on the salt water. No damages done.

Upon further digging, there are many types of stainless steel material used for different types of bearings with different applications, appearance alone is the wrong criteria to judge what's good for your reel. Apparently, bearing B was made using Si3N4 ceramic balls and SAE408 grade stainless steel designed for high speed and high temperature application in or near RC engines but poor corrosion resistance. That's why they are for RC applications where there's plenty of lubrication with little exposure to corrosive elements.

I can't find any information about Shimano's S-ARB material but I hear they are specially coated with nickel and the manufacturing of this coating is rather expensive. With special coating means high precision was also difficult to achieve. But their coating seems to hold up well but there are plenty of jammed up S-ARB bearings out there to know that these coatings wear off over time and reel maintenance isn't exactly at the top of people's mind.

Bearing D is an interesting proposition with a unique stainless steel material that are much more affordable to produce and high precision can be easily attained for our angling application especially salt water exposure.

Bearing E seems to be targeted at bait casters to achieve high speed spooling and distance casting. The ceramic balls are Si3N4 and the stainless steel are of SAE440 (material for replica katana/swords stainless steel which is hardened through heat-treatment), that's how high precision of ABEC-7 can be achieve on a hybrid ceramic bearings. It holds up pretty well against salt water corrosion but I would make sure I rinse them clean with fresh water after salt water abuse as it is designed for fresh water and high speed application.

So, SAE what? Different applications require different bearings and there hasn't been a one size fits all bearing. Good quality full ceramics are too expensive and the affordable ones aren't built to high precision standards. I also read somewhere that it's very difficult to manufacture these micro bearings in full ceramics as they require thin materials and very difficult to achieve it's intended potential and precision due to its natural properties of being brittle. Full ceramics can only take a fraction of the load as compared to an equivalent stainless steel bearing hence different parts of the reel with different types of load would need different type of bearing specifications (if you are anal about being specific).

Hope this answers most if not some of your queries about the type of bearings to go with.